Have you ever wondered what it’s like behind the scenes at Arthur Price? What happens before our silverware adorns your dinner table? And what gives it that lasting power that means it can be passed down through the generations? Read on for an exclusive insight into how it all comes together!

For over a century, Arthur Price cutlery has been a hallmark of beautiful silverware and manufacturing excellence, made right here in the UK. Usually in our blog, we take you on a culinary journey, from the latest delicious recipes to top table etiquette tips.

But today, we’re inviting you to join us on a different journey. Here’s your exclusive visit to the Arthur Price factory in Sheffield. Get a unique insight into the production process and see how we achieve the very highest standards of quality.

Silver service

We manage our products through the full life cycle – from cooking up stunning designs to seeing them through to final production.

Here, we’re at the polishing stage. As you can see, our latest batch of stainless-steel spoons have been fixed into a jig with the aid of clamps. The operator has prepared these ready for them to be multi-polished.

Teamwork

Each member of the team on the factory floor plays a key role in ensuring the highest quality from our machinery.

On the left, the operator can be seen manually inserting the jig into the multi-polishing machine for the spoon bowls to be polished. On the right, the machine is in action, thoroughly polishing the bowls of the spoons to ensure they give off our signature shine!

Stamp of approval

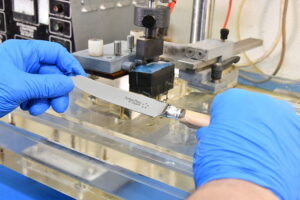

Here, the operator is ‘backmarking’ the reverse side of a fork with our branding – after all, our name is synonymous with the highest quality tableware!

Nothing but perfection

Creating timeless style has been our passion since our beginnings in 1902, and only perfection will do. A key part of the factory process – and quite literally testing our ‘metal’ – is therefore the inspection stage.

For this, we’re moving into the warehouse, under quality lighting. The inspector is shown wiping a spoon over with cotton gloves while looking for any abnormalities within the item.

If any variances are found, the item would be sent back out onto the factory floor. If our inspector is happy, we’re happy! It’s then ready to join a full set and be packed ready for dispatch. Will it be adding some shimmer to your dining table?

We hope you’ve enjoyed this glimpse into where the magic happens in the Arthur Price factory. As you can see from our range, the result of this manufacturing process is something very special. View our full collection here